Cross-slip of long dislocations in FCC solid solutions. Tensile properties of low-stacking fault energy high-entropy alloys. Superior high tensile elongation of a single-crystal CoCrFeNiAl 0.3 high-entropy alloy by Bridgman solidification. High manganese austenitic twinning induced plasticity steels: a review of the microstructure properties relationships. Multiscale mechanics of TRIP-assisted multiphase steels. Brittle intermetallic compound makes ultrastrong low-density steel with large ductility. Ductile CoCrFeNiMo x high entropy alloys strengthened by hard intermetallic phases. Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Size effect, critical resolved shear stress, stacking fault energy, and solid solution strengthening in the CrMnFeCoNi high-entropy alloy. A statistical theory of solid solution hardening. Concepts of the Electron Theory of Alloys (IOM Communications, 1998). Transition metals: d-band hybridization, electronegativities and structural stability of intermetallic compounds. Tunable stacking fault energies by tailoring local chemical order in CrCoNi medium-entropy alloys. Chemical short-range orders and the induced structural transition in high-entropy alloys. Local structure and short-range order in a NiCoCr solid solution alloy. Atomic-scale properties of Ni-based FCC ternary, and quaternary alloys. Tamm, A., Aabloo, A., Klintenberg, M., Stocks, M. Hybrid Monte Carlo/molecular dynamics simulation of a refractory metal high entropy alloy. Processing, microstructure and mechanical properties of the CrMnFeCoNi high-entropy alloy. Concentration waves and Fermi surfaces in random metallic alloys. Theory of Structural Transformations in Solids (Dover, 2013). A critical review of high entropy alloys and related concepts. Microstructures and properties of high-entropy alloys. Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off. Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures. Nanoscale origins of the damage tolerance of the high-entropy alloy CrMnFeCoNi. A fracture-resistant high-entropy alloy for cryogenic applications. Microstructural development in equiatomic multicomponent alloys. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Mapping atomic-scale element distributions opens opportunities for understanding chemical structures and thus providing a basis for tuning composition and atomic configurations to obtain outstanding mechanical properties.

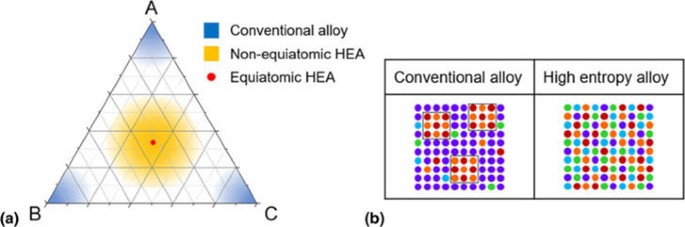

These deformation mechanisms in the CrFeCoNiPd alloy, which differ markedly from those in the Cantor alloy and other face-centred cubic high-entropy alloys, are promoted by pronounced fluctuations in composition and an increase in stacking-fault energy, leading to higher yield strength without compromising strain hardening and tensile ductility. In situ transmission electron microscopy during straining experiments reveals massive dislocation cross-slip from the early stage of plastic deformation, resulting in strong dislocation interactions between multiple slip systems. The resulting nanoscale alternating tensile and compressive strain fields lead to considerable resistance to dislocation glide. By contrast, in the CrFeCoNiPd alloy, in which the palladium atoms have a markedly different atomic size and electronegativity from the other elements, the homogeneity decreases considerably all five elements tend to show greater aggregation, with a wavelength of incipient concentration waves 11, 12 as small as 1 to 3 nanometres. In the Cantor alloy, the distribution of the five constituent elements is relatively random and uniform. Here we use atomic-resolution chemical mapping to reveal the element distribution of the widely studied face-centred cubic CrMnFeCoNi Cantor alloy 2 and of a new face-centred cubic alloy, CrFeCoNiPd. Rational design of such alloys hinges on an understanding of the composition–structure–property relationships in a near-infinite compositional space 9, 10. Their unconventional compositions and chemical structures hold promise for achieving unprecedented combinations of mechanical properties 3, 4, 5, 6, 7, 8. High-entropy alloys are a class of materials that contain five or more elements in near-equiatomic proportions 1, 2.

0 kommentar(er)

0 kommentar(er)